Introduction

Polyglyceryl-3 Methylglucose Distearate is a strong, plant-derived emulsifier that has become a preferred choice among modern cosmetic chemists.

It is widely praised for creating stable, aesthetic oil-in-water (O/W) emulsions without the need for ethoxylation.Often marketed under trade names like Tego Care 450, this ingredient allows for the creation of sophisticated textures ranging from light lotions to heavy, protective creams.

For formulators seeking to move away from PEGs (polyethylene glycols) while preserving high performance, this emulsifier offers a reliable solution. It provides exceptional stability against heat and cold, rendering it ideal for products destined for varying climates.

Quick Facts

- INCI Name: Polyglyceryl-3 Methylglucose Distearate

- Function: Non-ionic O/W Emulsifier, Emollient, Texture Enhancer

- Origin: 100% Plant-based (typically Corn and RSPO Palm Oil)

- HLB Value: Approximately 12 (creates Oil-in-Water emulsions)

- Typical Usage Rate: 2.0% – 4.0% (can be lower if using co-emulsifiers)

- Solubility: Soluble in warm oil; dispersible in water.

- Optimal pH Range: Stable across pH 4.5 – 8.5.

- Processing: Requires heating to 80°C in the oil phase.

- Safety Note: Usually mild and non-irritating, but always ensure broad-spectrum preservation in water-containing formulas.

What is Polyglyceryl-3 Methylglucose Distearate?

This ingredient is a diester of stearic acid and the polyglyceryl ether of methylglucose. Chemically, it combines the hydrophilic (water-loving) properties of polyglycerin and glucose with the lipophilic (oil-loving) properties of stearic acid.

This unique hybrid structure gives it powerful emulsifying capabilities. Unlike simple soaps or basic esters, the glucose backbone provides distinct hydration benefits. It binds water effectively, helping to immediately hydrate the skin upon application.

Because it is non-ionic, it carries no electrical charge. This makes it highly adapted to a wide range of active ingredients, including cationic conditioning agents and sensitive botanical extracts that might destabilize in ionic systems.

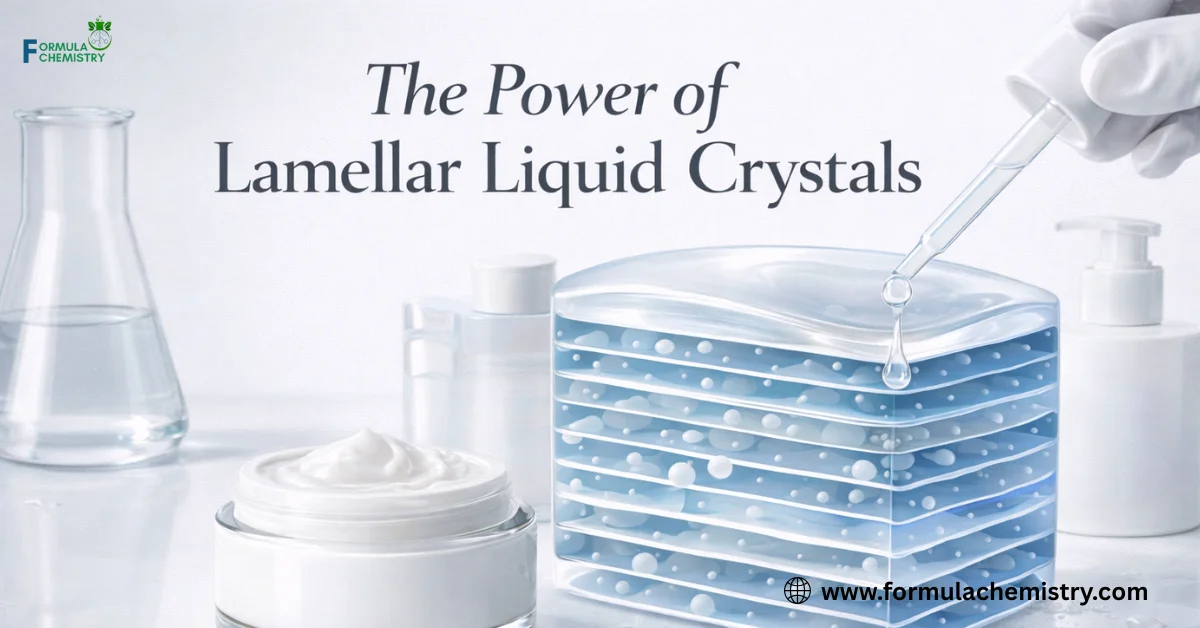

The Power of Lamellar Liquid Crystals

The true “superpower” of Polyglyceryl-3 Methylglucose Distearate is its ability to form lamellar liquid crystals. These are organized structures where oil and water layers alternate in a stable, repeating pattern.

These structures are significant because they closely resemble the intercellular lipid matrix of the human stratum corneum. This biomimetic nature permits emulsions made with this ingredient to reinforce the skin barrier physically.

Furthermore, lamellar networks trap water effectively, offering long-lasting moisturization. They also act as a reservoir for active ingredients, which may enhance their delivery and lengthen their activity on the skin.

Sensory Profile and Texture

Formulators choose this emulsifier when they want a product that feels “expensive.” It imparts a glossy, shiny appearance to creams and grants a rich, cushioned feel during rub-out.

Despite its richness, it does not leave a waxy or tacky after-feel. Once absorbed, it leaves the skin feeling soft and conditioned, often described as a “velvety” finish. This makes it multifunctional enough for both heavy night creams and lighter day lotions.

It works exceptionally well with vegetable oils and silicones alike. Whether you are using heavy shea butter or light caprylic/capric triglycerides, Polyglyceryl-3 Methylglucose Distearate can stabilize the lipid phase without separating.

Formulating with Accuracy: Process and Stability

Using Polyglyceryl-3 Methylglucose Distearate requires compliance with particular processing parameters. It is a solid, waxy pellet at room temperature and must be melted.

It should be added to the oil phase and heated to roughly 80°C. It is critical that both the oil and water phases are at the same temperature (approx. 75°C–80°C) before combining to ensure proper emulsification.

High-shear mixing (homogenization) is recommended to reduce particle size and establish the lamellar network. However, prolonged high shear after the emulsion has formed and cooled can sometimes disrupt the liquid crystals, so switch to gentle stirring during the cool-down phase.

Common Problems and Fixes

Even robust emulsifiers can cause challenges if not handled correctly. Below are common issues formulators face with this ingredient and how to resolve them.

- Problem: The cream looks grainy or has small white specks.

- Fix: The oil phase was not heated enough to fully melt the distearate. Ensure the oil phase reaches 80°C and is fully clear before mixing.

- Problem: The emulsion is too thin or runny.

- Fix: This emulsifier builds viscosity over 24–48 hours. Allow the product to rest. If still thin, increase usage to 3.0% – 4.0% or add a fatty alcohol like Cetyl Alcohol.

- Problem: Phase separation after a few days.

- Fix: Inadequate homogenization or temperature mismatch. Make sure both phases are at 75°C+ when combined. Check that the pH is within the stable range (4.5 – 8.5).

- Problem: “Soaping” or whitening effect upon application.

- Fix: This is common with high-HLB emulsifiers. Add Dimethicone (1-2%) or a small amount of a low-HLB co-emulsifier (like Glyceryl Stearate) to reduce surface tension.

Boosting Stability with Co-Emulsifiers

While Polyglyceryl-3 Methylglucose Distearate can function as a primary emulsifier, it performs best when supported. Pairing it with fatty alcohols is standard practice.

Adding Cetearyl Alcohol or Behenyl Alcohol at 1.0% – 3.0% greatly enhances the viscosity and stability of the lamellar gel network. This combination creates a strong chassis that can support high loads of oil or difficult activities.

For formulations containing a high water content, adding a water-phase stabilizer is also crucial. Xanthan Gum or Sclerotium Gum at 0.2% – 0.5% will prevent water mobility and ensure the emulsion remains homogeneous over time.

Comparative Benefits and Applications

When selecting a “green” or PEG-free emulsifier, the choices can be overwhelming. Polyglyceryl-3 Methylglucose Distearate stands out because of its balance of cost, performance, and sensory appeal.

Unlike some natural emulsifiers that can feel draggy or soap heavily (like some stearic acids), this ingredient offers a premium sensory sensation. It is also more robust than many “cold process” emulsifiers, which commonly struggle with high oil loads or temperature fluctuations.

It is especially well-suited for sensitive skin formulations. Because it is PEG-free and mimics skin lipids, it has a low potential for irritation and supports barrier recovery functions.

Ingredient Comparison Table

To help you decide if this is the right emulsifier for your project, compare it to other common PEG-free options below.

Table: Polyglyceryl-3 Methylglucose Distearate vs. Alternatives

| Feature | Poly-3 Methylglucose Distearate | Glyceryl Stearate SE | Cetearyl Olivate (and) Sorbitan Olivate |

| Primary Use | High-performance creams, sensitive skin | Basic lotions, budget formulas | “Natural” branding, liquid crystals |

| HLB Value | ~12 (O/W) | ~12 (O/W) | ~9 (O/W) |

| Texture | Glossy, rich, velvety | Matte, sometimes soapy | Waxy, dry, matte finish |

| Stability | Excellent (Heat/Freeze) | Moderate (pH sensitive) | Good, but needs stabilization |

| pH Range | 4.5 – 8.5 | 5.5 – 9.0 (Anionic) | 3.0 – 8.0 |

| Charge | Non-ionic | Anionic (usually) | Non-ionic |

Best Product Applications

Due to its usefulness, this emulsifier is found in a wide array of commercial products. It is excellent for Barrier Repair Creams, where the lamellar structure aids in restoring compromised skin.

It is also a top choice for Sunscreens. Its ability to disperse pigments and oils evenly helps improve the SPF performance and reduces the whitening effect of physical blockers like Zinc Oxide.

Finally, it is ideal for Baby Care Products. Its mildness, combined with its ability to stabilize high oil loads (for diaper creams or lotions), makes it a safe and effective choice for delicate skin.

FAQ’s about Polyglyceryl-3 Methylglucose Distearate: Skincare Powerhouse

Is Polyglyceryl-3 Methylglucose Distearate natural?

Yes, it is generally considered natural. It is derived from renewable plant sources like corn (for the glucose) and vegetable oils (for the stearic acid). It is often approved by natural certification bodies like COSMOS and ECOCERT.

Is it safe for acne-prone skin?

Generally, yes. While it contains stearic acid derivatives, the finished emulsifier is not inherently comedogenic for most people. However, the richness of the final cream depends on the oil phase; heavy oils paired with it may trigger acne.

Can I use it in a serum?

It is possible, but challenging. This ingredient naturally builds viscosity and opacity, making it better suited for creams and lotions. For clear or very fluid serums, a solubilizer or a different polymeric emulsifier would be more appropriate.

Does it require a co-emulsifier?

Technically, no, but practically yes. While it can work alone, professional formulations almost always pair it with a fatty alcohol (like Cetyl Alcohol) or a low-HLB co-emulsifier (like Glyceryl Stearate) to guarantee long-term shelf stability.

What is the difference between this and Glyceryl Stearate SE?

Glyceryl Stearate SE is anionic and pH sensitive (it can break if the product is too acidic). Polyglyceryl-3 Methylglucose Distearate is non-ionic, more robust, and stable across a wider pH range, including acidic toner-creams.

Is it vegan?

Yes, typically. The feedstock is almost exclusively plant-based (corn, palm, rapeseed, etc.). However, consistently verify with your specific supplier’s technical data sheet to ensure no animal-derived processing aids were used.

Why is my lotion separating?

The most common reasons are insufficient heat during processing (must reach 80°C) or a lack of water-phase stabilizer (like Xanthan Gum). Also, ensure your oil phase percentage isn’t too low; it likes an oil phase of at least 10-15%.

Can I use it for water-in-oil (W/O) emulsions?

No. With an HLB of approximately 12, it is strictly an oil-in-water (O/W) emulsifier. It is designed to disperse oil droplets into a water base, not the other way around. Use Polyglyceryl-3 Polyricinoleate for W/O systems.